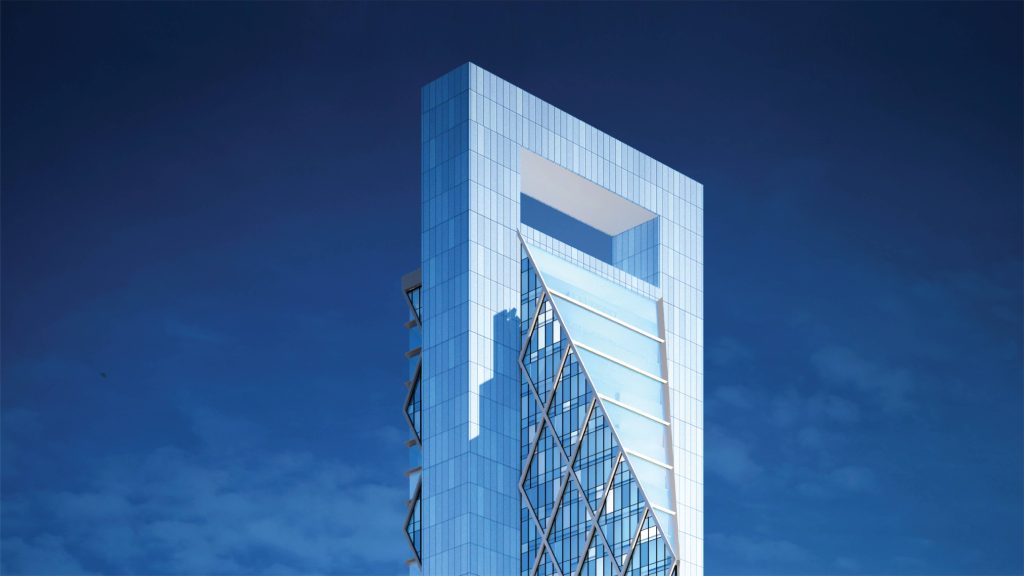

We are sharing a recent experience of a record volume of concrete casted at a time, to a raft foundation for a high-rise building at Mexico square. We felt the lessons learned are unique and would be of interest to architects and engineers.

Our firm obtained the Oromia Insurance headquarters building project in an architectural design competition held in 2019. The site is located in a prominent junction at Mexico Square, in front of Wabeshebele Hotel, adjacent to the Ethiopian Coffee and Tea Authority Building.

There are a lot of interesting architectural stories about this project, which will be shared in the future. But what prompted us to write this article is the volume of concrete we had pumped into the foundation for this high-rise building at a time. The foundation of this 40 story building is a 3m thick raft foundation. Being only a raft, that is without foundation piles, itself is unique. The foundation sits on a rock 20m below ground providing five basement floors. A record 6000m3 of concrete was pumped to the foundation at one time; or a 3,000,000 kg of cement (30,000 quintals of cement).

The thought of casting 6000m3 at a time was a nightmare for the design team. There was no experience of managing this size of concrete at a time in the country. And there is also the issue of the site, a location super busy with people and vehicular traffic – with a very limited access to pour concrete.

As a design team, we have been contemplating over this challenge for long time. We were concerned that with the limited space and pumping possibility, how such volume of concrete could be casted without forming a cold joint. We knew it would take a few days to cast such volume of concrete.

We requested the contractor to provide us a methodology how they would accomplish such an extensive volume of concrete at a time. But did not respond to our requests. The contractor, China Jiangxi, is a Chinese company with an extensive experience. The time came close and we called for a meeting. By that time the contractor has already identified an experienced concrete supplier by the name Gentium Concrete Technology. Gentium is also a company with a good experience in Dubai. We held a series of meetings and shared our concerns and demanded both teams for a methodology. But they don’t seem to be worried about it. When the contractor did not provide a methodology, we came up with one and shared it in one of our joint pre-concrete meetings. It seems both the contractor and the concrete supplier had a methodology in mind. We came to understand later that in their experience such concrete would be laid in layers. We argued with the limited number of concrete pumps they would be able to deploy that this strategy would obviously form cold joints. And there is also a shortage of cement in the country which the supplier had plans to supply only about 1,200m3 per day. This would mean it would take five days to complete.

Our team insisted that the methodology should be something that would start from one end of the site and that would quickly build up to reach the top of the raft, the 3m. Then we would follow it down. Luckily our floor plan is of an elongated rectangle of about 30x90m and with a sharp tip. Theoretically, this idea looked logical to quickly pile up the intended 3m level. We proposed to start the casting at that tapering tip.

We made a simple physical model to explain the idea to the contractor. On the day of the casting, we found out that the concrete pumps were set differently. We thought at first it was because of the challenge of the site. But when we started pumping concrete the contractor team was fixed for the same traditional layering method. We argued right on site, as the concrete was advancing, to return to the methodology already agreed upon. After a fierce argument, the agreed strategy was adhered. We managed to reach the 3m top level at the corner after about 12 hours of frustrating concrete pumping exercise; and finally got a relief.

Another challenge was that the concrete was being cast in the midst of a rainy season. The tight site had obliged us to build first a concrete trimmer, which acted as a drainage ditch including during casting. It is like doing the backfill first and building your foundation afterward. The trimmer acted as a formwork for the raft foundation.

We installed thermometers in three layers at 10 locations and gauged the inner temperature of the raft concrete. In the early days the heat of the middle layer reached over 90o C. But what was important was that the temperature difference between the top and the middle layer is maintained within the recommended temperature range to avoid surface cracks.

The concrete supplier had already modeled the concrete and provided us a recommendation. They had also advised us to seal the concrete top from the outside for about seven days until the concrete sets, and before curing begins.

The concrete work took one more day from what was originally planned due to a shortage of cement. The first concrete truck left the batching plan on Thursday afternoon at 01:37 PM, 30 June 2022; and the last truck arrived on site on Wednesday evening at 7:48 PM, 06 July 2022. All in all, took about six days of a round the clock work – our team working in a 12-hour shift of 3 to 3 AM/PM. It ended up being a success story.